Proven Energy Savings with Rapid Payback

TAS Thermal Blanket Solutions for steam systems offer demonstrated reductions in energy loss, with payback periods generally between 4 - 16 months. Once installed, the blankets provide immediate improvements in efficiency and operational cost reduction.

Immediate Energy & Environmental Impact

By reducing surface heat loss, TAS blankets lower fuel consumption, CO2 emissions, and ambient temperatures. These measurable results support sustainability targets while contributing directly to reduced operating expenses.

Improved Safety Conditions

Insulating high-temperature surfaces significantly reduces the risk of burn injuries and helps facilities comply with occupational safety requirements. Maintaining safe surface temperatures creates a more secure and productive work environment.

Precision-Engineered Insulation

Each blanket is CAD custom designed and fabricated to match valves, boiler doors, manways, flanges, expansion joints, flowmeters, PRV stations, condensate pumps, and associated piping. This ensures accurate fit, consistent performance, and ease of handling during operation or maintenance.

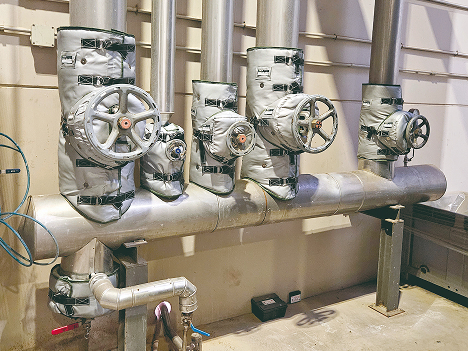

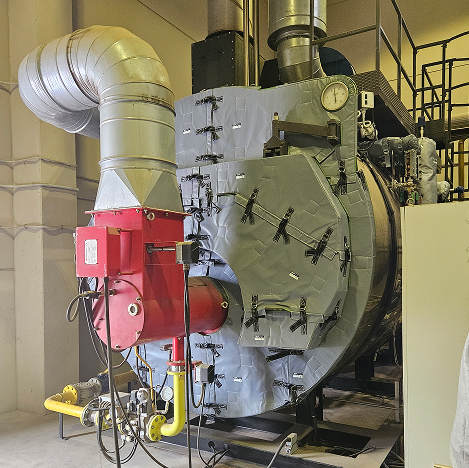

BOILER ROOM – MAIN HP STEAM HEADER

Design: LT450TT – 1.5” thickness

Fastener: Stainless Steel Wiretwists and Velcro® Flaps

BOILER ROOM – MAIN HP STEAM HEADER

Design: LT450TT – 1.5” thickness

Fastener: Stainless Steel Wiretwists and Velcro® Flaps

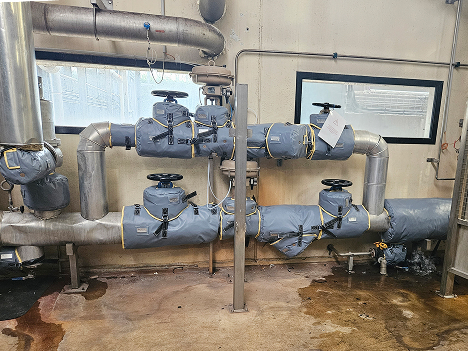

BOILER ROOM – MAIN HP STEAM HEADER

Design: LT450TT – 1.5” thickness

Fastener: Stainless Steel Wiretwists and Velcro® Flaps

BOILER ROOM – MAIN HP STEAM HEADER

Design: LT450TT – 1.5” thickness

Fastener: Stainless Steel Wiretwists and Velcro® Flaps

BOILER ROOM – MAIN HP STEAM HEADER

Design: LT450TT – 1.5” thickness

Fastener: Stainless Steel Wiretwists and Velcro® Flaps

BOILER ROOM – MAIN HP STEAM HEADER

Design: LT450TT – 1.5” thickness

Fastener: Stainless Steel Wiretwists and Velcro® Flaps

Removable & Reusable

TAS blankets are designed for repeated removal and reinstallation, making them practical for areas that require regular inspection or servicing. Reinstallation takes minutes instead of hours, minimizing downtime and labor costs. In many cases, a single reuse offsets the cost compared to conventional insulation replacement.

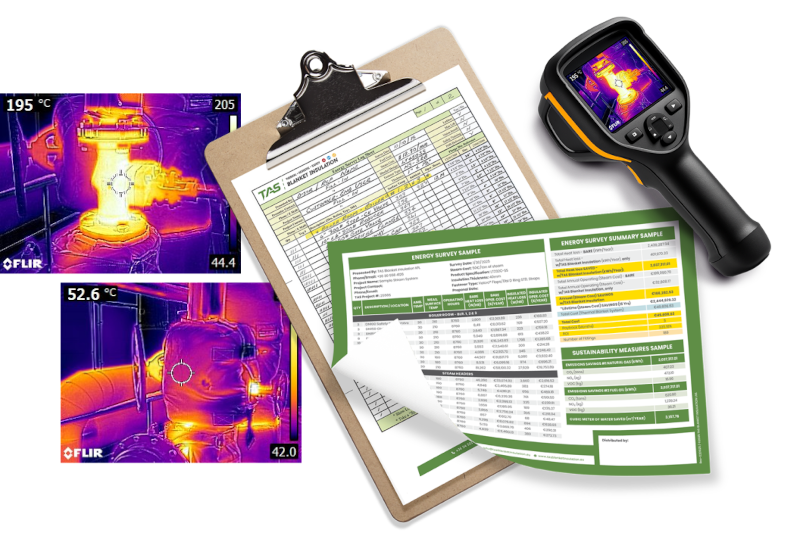

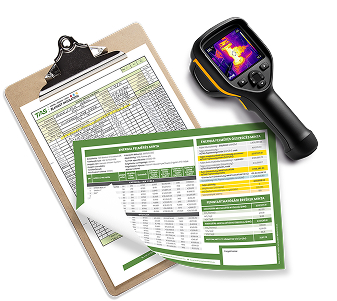

Energy Survey Services

A TAS Energy Survey identifies and quantifies every insulation opportunity within the steam system. The survey documents fittings and equipment, measures surface temperatures, and evaluates energy losses. Based on these findings, TAS provides a detailed proposal outlining expected savings and payback period. Typically achieve payback within 10 months or less.

Complete Turnkey Service

From initial survey through design, fabrication, shipping and installation, TAS delivers a complete, managed process. Projects are executed by trained specialists to ensure proper fit, reliable performance, and timely implementation. With an expected service life of approximately 15 years and virtually no maintenance requirements, TAS Thermal Blanket Solutions provide durable and cost-effective insulation for critical steam applications.