Reduce Harmful noise at the source!

Industrial facilities face difficult noise challenges: high-decibel compressors, chillers, blowers, pumps, fans, engines, and vibrating pipelines that exceed workplace limits and disrupt operations. These noise levels affect not only production floor workers, but also office personnel, control room staff, and even neighboring buildings when equipment is located close to occupied areas.

TAS Acoustic Blanket Insulation is engineered to reduce noise directly at the source, using a flexible, multi-layer design that fits even the most irregular equipment surfaces.

TAS acoustic blankets provide targeted noise control across a wide range of machinery:

Designed through CAD technology, each blanket is custom-fit to existing equipment, delivering effective acoustic control where rigid enclosures cannot be used. The design, construction and fastening system allow quick installation and removal without special tools, ensuring simple handling during maintenance.

Depending on the sound profile and installation conditions, TAS acoustic blankets can achieve up to 16 dB(A) of noise reduction. This provides immediate improvements in:

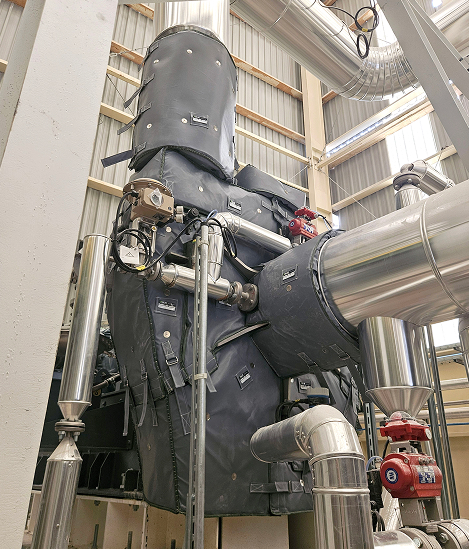

BOILER ROOM – MAIN HP STEAM HEADER

Design: LT450TT – 1.5” thickness

Fastener: Stainless Steel Wiretwists and Velcro® Flaps

BOILER ROOM – MAIN HP STEAM HEADER

Design: LT450TT – 1.5” thickness

Fastener: Stainless Steel Wiretwists and Velcro® Flaps

TAS acoustic blankets are built for long-term performance in demanding industries.

While protecting our proprietary manufacturing details, we ensure every blanket incorporates:

This results in a reliable, professional-grade solution suitable for compressors, chillers, blowers, pumps, and other mission-critical equipment.

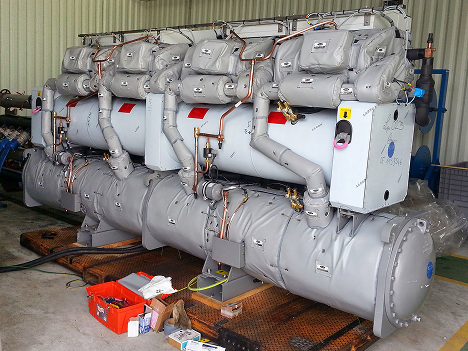

BOILER ROOM – MAIN HP STEAM HEADER

Design: LT450TT – 1.5” thickness

Fastener: Stainless Steel Wiretwists and Velcro® Flaps

BOILER ROOM – MAIN HP STEAM HEADER

Design: LT450TT – 1.5” thickness

Fastener: Stainless Steel Wiretwists and Velcro® Flaps

BOILER ROOM – MAIN HP STEAM HEADER

Design: LT450TT – 1.5” thickness

Fastener: Stainless Steel Wiretwists and Velcro® Flaps

BOILER ROOM – MAIN HP STEAM HEADER

Design: LT450TT – 1.5” thickness

Fastener: Stainless Steel Wiretwists and Velcro® Flaps

BOILER ROOM – MAIN HP STEAM HEADER

Design: LT450TT – 1.5” thickness

Fastener: Stainless Steel Wiretwists and Velcro® Flaps

BOILER ROOM – MAIN HP STEAM HEADER

Design: LT450TT – 1.5” thickness

Fastener: Stainless Steel Wiretwists and Velcro® Flaps

Removable, Reusable & Maintenance-Friendly

TAS acoustic systems are designed for fast service access.

Blankets are fully removable and reinstall in minutes using:

No tools are required, allowing maintenance teams to work efficiently without disturbing equipment alignment or mounting points.

Turnkey Support

TAS provides complete support throughout your project:

Our approach ensures a predictable, professional solution that enhances workplace safety and noise compliance.