Energy-Efficient Insulation for Tire Presses, Steam Systems & Process Equipment

TAS provides engineered removable-reusable insulation systems specifically designed for tire curing presses, steam distribution lines, mixers, extruders, and calendering equipment used in tire manufacturing. These systems significantly reduce heat loss and improve temperature stability, delivering measurable benefits in energy savings, product quality, and workplace safety—critical factors in high-energy, continuous production environments.

Energy Efficiency & Cost Savings

Tire curing presses consume large amounts of energy to maintain precise mold temperatures. Without insulation, these surfaces radiate heat continuously, leading to wasted energy and higher operating costs. TAS blankets reduce surface heat loss by up to 90%, lowering steam consumption and electricity usage. Most installations achieve a return on investment in 3–7 months, with continued savings over the blanket’s full service life.

Improved Curing Performance & Product Consistency

Temperature stability directly affects cure uniformity, tire quality, and cycle time. Uninsulated presses lose heat unevenly, causing longer curing cycles and potential inconsistencies. TAS insulation helps maintain optimal, uniform mold temperatures, improving cure rate efficiency and supporting consistent rubber properties and tire performance.

Workplace Safety & Ambient Temperature Control

Tire presses and steam equipment can reach high surface temperatures, creating severe burn hazards and excess radiant heat in production areas. TAS blankets reduce exposed surface temperatures, enhancing worker safety, improving comfort, and reducing factory cooling loads — particularly important in high-volume manufacturing facilities.

Extended Equipment Life & Reduced Maintenance

Thermal insulation reduces heater cycling and minimizes stress on electrical and steam system components. This leads to longer equipment life, lower maintenance frequency, and fewer unplanned stoppages—supporting continuous production targets and uptime requirements.

Environmental & Sustainability Benefits

Energy efficiency is a major contributor toward decarbonization in tire manufacturing. By lowering fuel and steam consumption, TAS insulation systems reduce CO₂ emissions and support compliance with corporate sustainability goals and regulatory requirements.

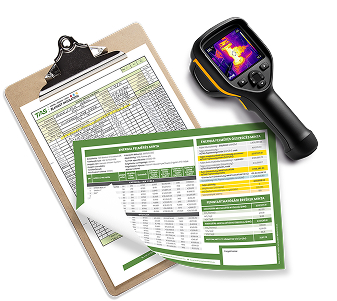

TAS blanket are custom CAD-designed to precisely fit complex geometries of tire presses, piping, valves, and other fittings. The removable-reusable design allows easy access for maintenance without damage, ensuring long-term usability.

BOILER ROOM – MAIN HP STEAM HEADER

Design: LT450TT – 1.5” thickness

Fastener: Stainless Steel Wiretwists and Velcro® Flaps

BOILER ROOM – MAIN HP STEAM HEADER

Design: LT450TT – 1.5” thickness

Fastener: Stainless Steel Wiretwists and Velcro® Flaps

Truly Removable & Reusable

Equipment, machinery, and fittings often require regular inspection, servicing, and maintenance. TAS insulation blankets are truly removable and reusable, designed with a user-friendly approach that allows quick removal and reinstallation. This minimizes downtime and labor while maintaining full insulation performance, making them ideal for continuous and high-availability operations.

Energy Efficiency & Payback

TAS blanket & jacket insulations deliver immediate energy savings by reducing surface heat loss and lowering ambient temperatures. Facilities typically achieve payback within 10 months or less and in many cases qualify for utility incentive programs that further improve ROI. Learn more about our Energy Savings.

Complete Turnkey Service

TAS provides complete end-to-end support, from energy surveys and incentive assistance through engineering, fabrication, and installation. Our solutions help customers reduce energy costs, improve operational efficiency, and maintain safe, compliant working environments across a wide range of industrial applications.