Engineered Insulation for ATEX Zones

TAS provides removable–reusable insulation systems engineered for equipment operating in explosive atmospheres. Our ATEX-rated blanket solutions are designed for various fittings and equipments that are in ATEX environments. Each blanket is built using ATEX-compatible, anti-static, and flame-retardent materials, ensuring temperature control, operational safety, and compliance with hazardous-area requirements.

Ignition Risk Reduction in ATEX Zones

Uninsulated hot surfaces present a direct ignition hazard in ATEX-classified areas. TAS blankets reduce external surface temperatures to safe levels, minimizing the risk of ignition from hot equipment. This prevents contact with flammable gases, vapors, or combustible dust settling on heated surfaces—one of the most common ignition sources in hazardous areas.

Stable Temperatures for Sensitive Processes

Heat loss in explosive atmospheres can disrupt process consistency, affect fluid viscosity, or create cold spots where condensation or solidification occurs. TAS ATEX insulation stabilizes temperature profiles, improves heater efficiency, and enhances overall process reliability—critical for chemical, pharmaceutical, food, and solvent-handling operations.

Compliance Support for ATEX Safety Requirements

TAS blankets contribute to compliance with ATEX directives by helping maintain equipment surface temperatures below defined ignition thresholds. Materials used in production are selected for anti-static behavior, flame resistance, and chemical compatibility. Documentation packages and material data sheets are available to support plant risk assessments and audits.

Protection for Equipment in Dust & Gas Hazard Zones

In ATEX dust zones, accumulation of powders on hot surfaces can create smoldering or flash combustion hazards. TAS insulation prevents hotspots, protects against dust layering, and ensures equipment remains safe during continuous operation. In gas zones, properly insulated components reduce the likelihood of hot-surface ignition and help maintain safe operating conditions.

TAS blanket are custom CAD-designed to precisely fit complex geometries of tire presses, piping, valves, and other fittings. The removable-reusable design allows easy access for maintenance without damage, ensuring long-term usability.

Extended Service Life in Harsh Environments

Equipment in hazardous areas is often exposed to corrosive chemicals, oils, solvents, and outdoor weathering. TAS ATEX-rated blankets are constructed from rugged, chemical-resistant fabrics and high-quality insulation cores, improving equipment longevity while reducing maintenance frequency in demanding environments.

Improved Worker Safety in Restricted Access Areas

ATEX zones typically have limited access and strict safety controls. TAS insulation maintains touch-safe surface temperatures, reducing burn hazards for instrumentation technicians and maintenance personnel working in confined or explosive-risk areas.

Custom Engineering for Complex Geometries

Valves, inline filters, manifold blocks, rotary valves, equipment, and extruder components often have irregular shapes that are difficult to insulate with traditional methods. TAS custom blankets ensure complete coverage, eliminating exposed hotspots and ensuring consistent ATEX-compliant thermal protection.

Designed for Moderate to High Temperatures

TAS ATEX blankets can be engineered for continuous use on high temperature applications, making them suitable for steam systems, reactors, solvent dryers, high-temperature pumps, and chemical process equipment operating in hazardous zones.

Environmental & Operational Benefits

By reducing heat loss and stabilizing process temperatures, ATEX-rated insulation lowers energy consumption and supports decarbonization efforts. The removable design avoids insulation waste, aligns with circular economy principles, and remains reusable over multiple maintenance cycles.

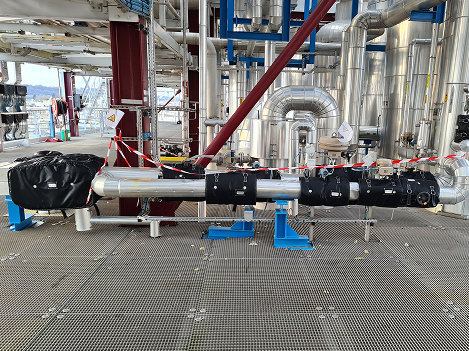

BOILER ROOM – MAIN HP STEAM HEADER

Design: LT450TT – 1.5” thickness

Fastener: Stainless Steel Wiretwists and Velcro® Flaps

BOILER ROOM – MAIN HP STEAM HEADER

Design: LT450TT – 1.5” thickness

Fastener: Stainless Steel Wiretwists and Velcro® Flaps

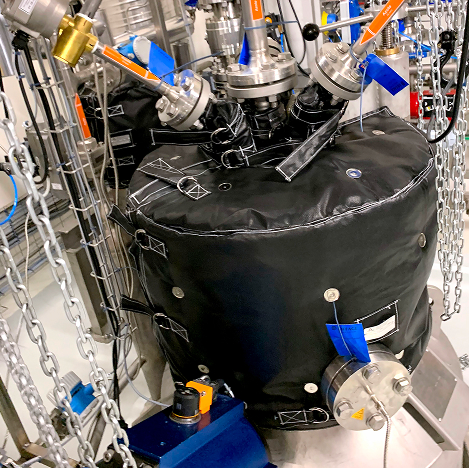

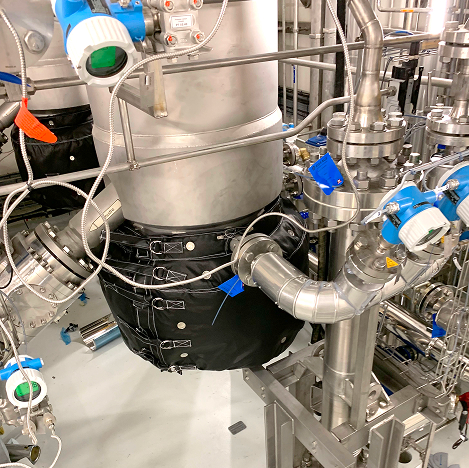

BOILER ROOM – MAIN HP STEAM HEADER

Design: LT450TT – 1.5” thickness

Fastener: Stainless Steel Wiretwists and Velcro® Flaps

BOILER ROOM – MAIN HP STEAM HEADER

Design: LT450TT – 1.5” thickness

Fastener: Stainless Steel Wiretwists and Velcro® Flaps

BOILER ROOM – MAIN HP STEAM HEADER

Design: LT450TT – 1.5” thickness

Fastener: Stainless Steel Wiretwists and Velcro® Flaps

Truly Removable & Reusable

Equipment, machinery, and fittings often require regular inspection, servicing, and maintenance. TAS insulation blankets are truly removable and reusable, designed with a user-friendly approach that allows quick removal and reinstallation. This minimizes downtime and labor while maintaining full insulation performance, making them ideal for continuous and high-availability operations.

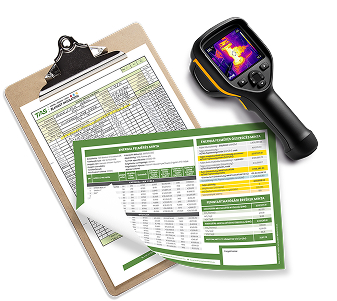

Energy Efficiency & Payback

TAS blanket & jacket insulations deliver immediate energy savings by reducing surface heat loss and lowering ambient temperatures. Facilities typically achieve payback within 10 months or less and in many cases qualify for utility incentive programs that further improve ROI. Learn more about our Energy Savings.

Complete Turnkey Service

TAS provides complete end-to-end support, from energy surveys and incentive assistance through engineering, fabrication, and installation. Our solutions help customers reduce energy costs, improve operational efficiency, and maintain safe, compliant working environments across a wide range of industrial applications.