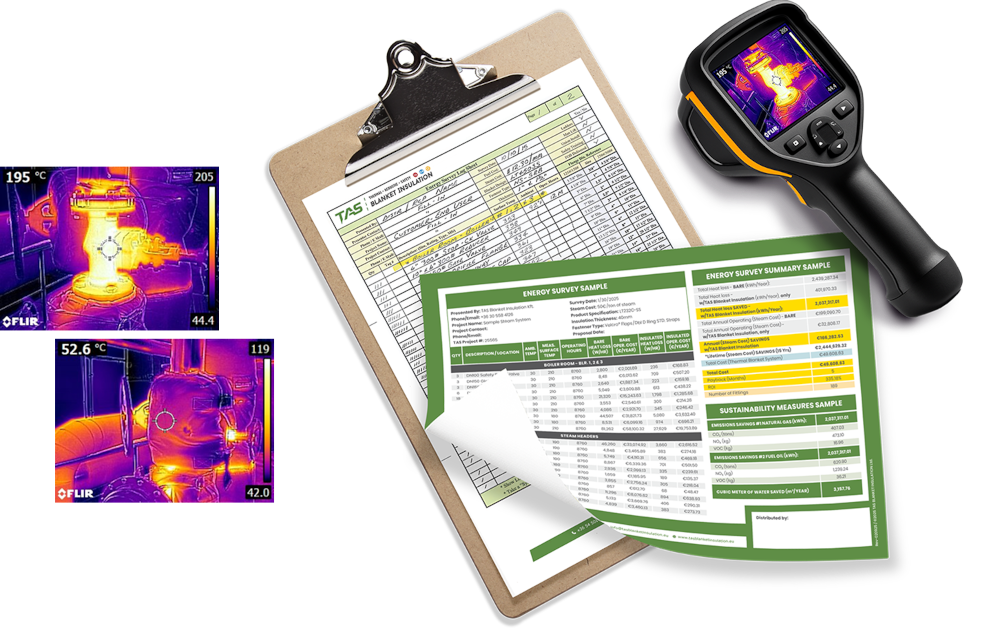

Today, several solutions are available to achieve more efficient insulation of industrial steam systems. Alongside traditional, rigid insulation methods, removable and reusable insulation blankets are gaining increasing importance. Their major advantage over traditional rigid insulation solutions is that while rigid systems can typically only be removed through destructive dismantling, these modern solutions can be removed […]